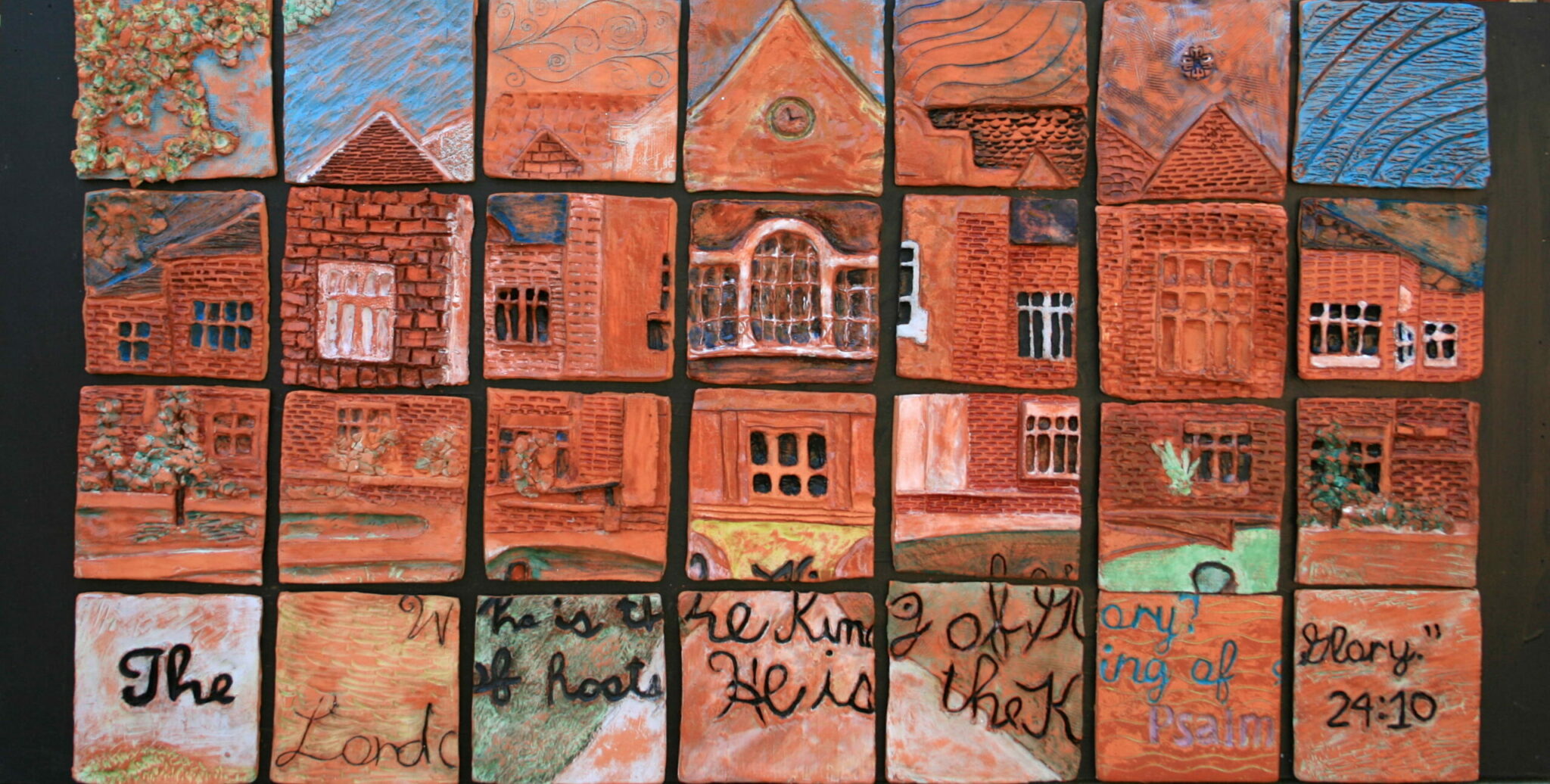

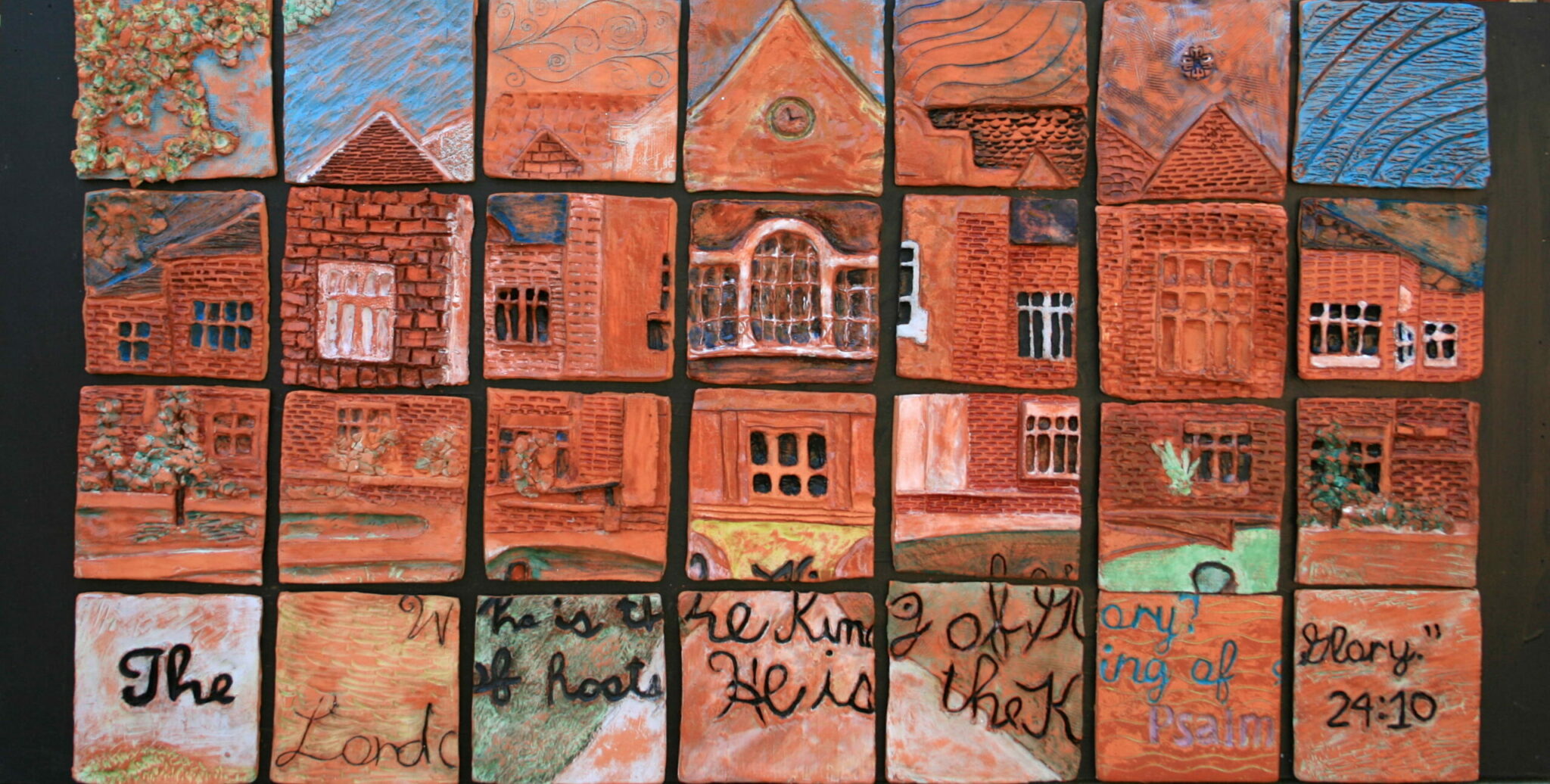

Collaborative Art Projects: Successful in 2D & 3D Art

A lesson about a collaborative relief sculpture project. Supplies and how to included. Learn how to implement this project in your classroom!

Read More

A lesson about a collaborative relief sculpture project. Supplies and how to included. Learn how to implement this project in your classroom!

Read More

An art lesson about fusing glass with a high school sculpture class. Instructions, supplies, pictures, and success stories included!

Read More